The launch of a $450-million project to turn a brewery in North Carolina into a pet-food factory lined up perfectly with the opening of a union training center in that state, providing hands-on learning for newly recruited SSMRC millwrights and a skilled labor force for contractors working at the site.

“One of the key points to take away is how this project has helped us start building a membership base around the new training center in Charlotte,” said Logan Brown, director of the SSMRC’s Eastern Region. “This project has helped us kick off our North Carolina membership drive with employment opportunities.”

The Eden, North Carolina, brewery began operating in 1978, and MillerCoors closed it in 2016. Nestle Purina announced in late 2020 that it was buying the 1,365-acre property. On Oct. 19, 2021, the company kicked off a project to convert 1.3 million square feet of space into a facility that will produce dog and cat food.

The first millwrights from the Southern States Millwright Regional Council arrived at the jobsite on Nov. 1, 2021, and the project is slated for completion in March of 2023. SSMRC millwrights have worked for three contractors at the site: Griffin Industrial Contracting; Superior Rigging & Erecting Company; and PSC Crane & Rigging. The millwright workforce peaked at 60 and, in August of 2022, was steady at 35 to 40 SSMRC members working 10 hours per day, six days a week, said Charles Smith, business agent for Millwright Local 1263, which covers the Carolinas and Georgia.

What’s involved

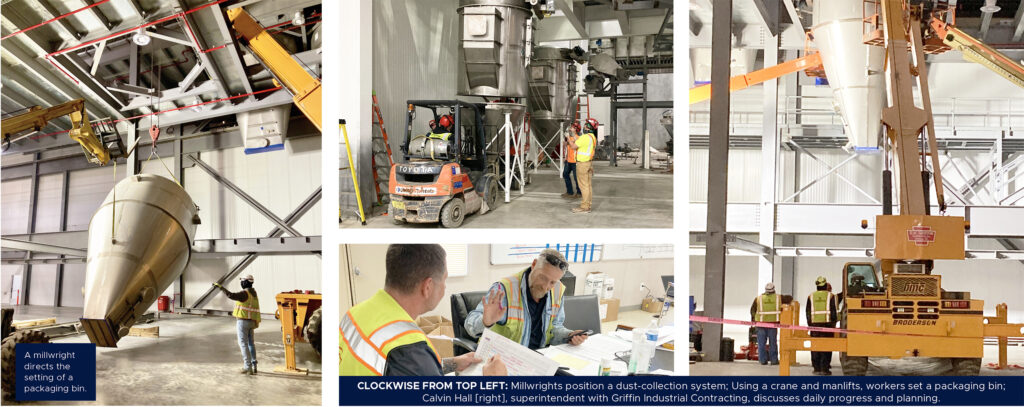

Millwrights are installing all the processing equipment, which includes grain hoppers, auger and screw conveyors, bucket elevators, pumps, and motors. They’re also staging machinery in the laydown yard, doing layout to determine where each piece of machinery will be installed, and using their rigging skills to transport equipment into the plant and properly position it.

Griffin Industrial is installing processing equipment that will produce dry dog food. Calvin Hall, superintendent with Griffin Industrial and a member of Millwright Local 1076, said the company is installing three dryer systems with a total of five dryers and 18 extruders organized into six banks.

Inside the 73-foot-tall structures millwrights are building, raw pet-food ingredients begin on the top floor and are funneled into a distributor, then to a mixer that blends in wet ingredients and coloring and cooks the food before it is sent to the extruders, which push the food through forms, giving individual pieces their shape. From there, the food goes into the dryers, then a coating and cooling system. Finally, it is piped into a packaging area.

Millwrights also are installing the conveyor machinery that shrink-wraps pallets of bagged dog food.

This is the first pet-food plant that Randall Johnson has worked in during 30 years as a millwright, but he said millwright tasks are similar to those performed in other food-grade plants. “I’ve done a lot of work at General Mills outside of Covington, Georgia, and in Atlanta, and right now the only difference is usually when I go into those food-grade plants, they’re already up and running,” said Johnson, a Local 1263 member. “So you’d have a few more rules to go by. We’re just getting this one built, so we’re not having to deal with hair nets and stuff like that.”

Johnson began the project as a foreman managing work on the extruder system. In the spring he moved up to general foreman and has overseen millwrights in many areas of the plant.

“They’re performing good quality work,” Hall said of the SSMRC millwrights. “We’re doing a lot of welding, both stick and TIG welding throughout the project. They have to be certified welders, and before you can proceed, Nestle has to come out and inspect your welds. We’ve not failed one yet.”

Membership drive

New millwrights and any workers who need welding training or certification can get those things at the United Brotherhood of Carpenters’ millwright and carpenter training center that opened in February of 2021 in Charlotte. It is the only certification center in the region, Hall said.

And the training center has helped with more than welding skills and tests. The membership drive the SSMRC held in conjunction with construction of the $5-million, state-of-the-art training center has helped staff the Nestle Purina project with millwrights skilled in all areas of the trade.

Business Agent Charles Smith relocated to Charlotte from North Augusta, South Carolina, and began recruiting before the project started.

“This was perfect timing for Charles’ relocation up there and for the opening of that center,” Brown said.

Growing pains

Smith said he was worried at first about Local 1263’s ability to provide adequate numbers of experienced millwrights. “The bulk of the membership that we had up here at the beginning was predominantly apprentices,” he said. “Griffin was gracious enough to go through those growing pains with those apprentices, and they loved them.”

Smith said he also credits existing Local 1263 members in the area with identifying non-union craftspeople, on and off the Nestle Purina jobsite, and sending them to local offices at the Charlotte training center, where they became members and then went to work for SSMRC partnering contractors at the pet-food plant in Eden.

Hall was able to help, too, by bringing 10 experienced millwrights from Griffin Industrial’s previous project, an Amazon facility in Durham, North Carolina, that wrapped up within 15 days of the Nestle Purina job starting.

Millwrights have been working in five-person crews that are a mix of journeypeople and apprentices. Johnson said the apprentices are all good hands and the variety of equipment being installed has made the project a great learning experience for them.

“Because the dryers are big pieces of equipment, they are learning a lot about rigging, but they also learn a lot about installation for the conveyors and equipment in general,” he said. “We’re doing layout for setting all the equipment, popping lines on the floor, and taking measurements. We’re shooting elevation with the transits and using transits and theodolites to do the layout.”

Smith said apprentices are learning to operate equipment including forklifts and aerial lifts. “Closer to the end of the project, there’s going to be a bunch of shaft and machinery alignment, pump and motor alignment, and motor and gearbox alignment going on as well,” he said. “So it’s a great job for an apprentice to start and finish because they’ll get to see the full gamut of typical millwright work for every industry except the power industry.”

Supply-chain challenges

Late in 2021 and during the first and second quarters of 2022, a bogged-down supply chain delayed the arrival from overseas of machinery millwrights were to install. Smith credits the leadership of Griffin Industrial and the millwright leaders at the site with maintaining momentum.

“They’ve been able to overcome and continue to move forward to completion on the project,” Smith said. “It would have been real easy for Griffin to say, ‘Hey guys, we don’t have any parts. Let’s go home until we get parts.’ But they didn’t say that. They found a way to work around and get some things done.”

Johnson said the millwrights concentrated on working where they could. “If we had to wait on something for one system, we’d just move to the next system and go ahead and build it as far as we could go and then when the parts came in, we would fall back and work on the first system,” he said.

By August of 2022, all the dryers were installed, the extrusion system was 65% complete, and the coating, cooling, and packaging areas were approximately 55% finished, Hall said.

Advantages of union labor

Once the Nestle Purina project is done, Local 1263 members’ next opportunity to work with Griffin Industrial will be at a First Quality diaper plant in Macon, Georgia.

Griffin Industrial is the new union arm of D.H. Griffin, a group of integrated contracting companies based in Greensboro, North Carolina. D.H. Griffin established Griffin Industrial after working successfully with the SSMRC and Local 1192 at the Mazda Toyota Manufacturing plant in Huntsville, Alabama, in 2020 and 2021. Griffin Industrial is now working on projects across the country and has signed collective bargaining agreements with six of the SSMRC’s locals and our parent organization, the United Brotherhood of Carpenters and Joiners of America.

Hall worked for D.H. Griffin at the Mazda Toyota plant and has been a superintendent for Griffin Industrial since it was founded. He said the young company has realized many benefits from utilizing union labor.

“We’re able to get ahold of the hall for resources to do good-quality work with trained professionals,” he said.