The vigilance of two UBC millwrights working at Sequoyah Nuclear Plant near Soddy-Daisy, Tennessee, prevented an emergency shutdown of a unit at the plant, which supplies electricity to approximately 1.3 million homes.

Employed by Siemens Energy in spring 2023, millwrights John Wolfe and Joe Bailess were part of a team inspecting and maintaining a low-pressure turbine during a scheduled outage at the Tennessee Valley Authority plant when they reported significant corrosion and a leak on equipment adjacent to the work area.

“The fact that it was noticed early and brought to the plant’s attention allowed TVA to make the repair and start the system without delay to operations,” said Richard Mason, Siemens Energy TVA Nuclear Alliance manager. “Had it gone unnoticed until scheduled system startup, it would have become emergent work.”

And if the leak, which occurred on the seal oil cooler reversing heads, had resulted in a ruptured pipeline while the unit was running, it would have forced a shutdown of the unit, said Steve Williams, nuclear representative for the SSMRC. “With that good catch while that unit was down, the problem was repaired so there wasn’t even a chance that it could have created a forced outage or shut down,” Williams said.

What’s a ‘Good Catch’?

According to The Ohio State University Environmental Health and Safety Program, a good catch is “recognition of an event or circumstance that had the potential to cause property damage or injury/illness, but did not occur thanks to a corrective action and/or timely intervention following the reporting.” It’s sometimes confused with a near miss, which is “an incident that took place without property damage or personal injury/illness, but where given a shift in time or position, damage or injury easily could have occurred.”

Steve Williams, nuclear representative for the SSMRC, further defines a good catch in the millwright world as: “When someone catches something ahead of an event or possible event. It could be a safety issue, and the good catch prevents an injury or fatality. A good catch might also prevent a shutdown or forced outage that could cost a significant sum of money for the facility owner, possibly millions. It could be a catastrophic failure that would cause damage to other equipment in a plant.”

Work Scope

Sequoyah Nuclear Plant is one of three nuclear power plants that are part of the Tennessee Valley Authority system, which serves all of Tennessee and parts of Alabama, Mississippi, Kentucky, Georgia, North Carolina, and Virginia. The Sequoyah plant consists of two units. In spring 2023, TVA conducted a refueling and maintenance outage of Unit 2. Three low-pressure turbines and one high-pressure turbine are part of that unit.

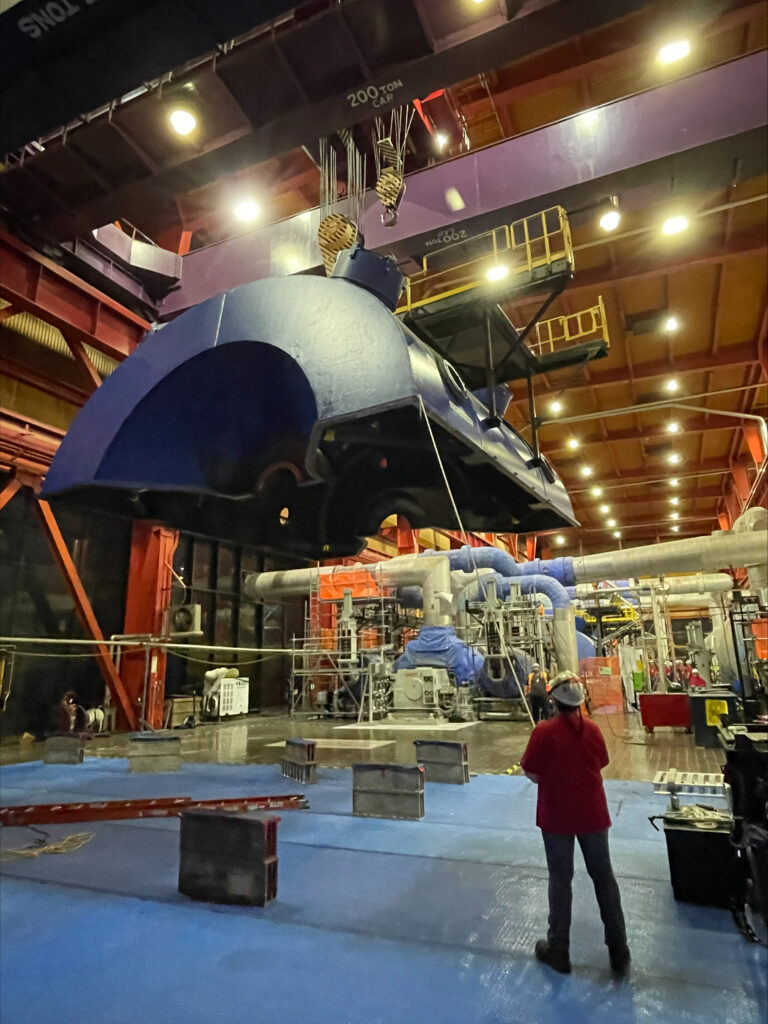

Siemens Energy Generating Services was charged with a slew of inspection and maintenance tasks focusing on Unit 2’s “Alpha” low-pressure turbine. These tasks included removing, dust blasting, and resetting a 225,000-pound rotor, replacing the exhaust hood, reheat valves, and intercept valves, disassembling, inspecting, and reassembling two throttle valves, and inspecting and performing necessary repairs on the turbine’s auxiliary system.

Millwrights critical to project

While Siemens put together a team of craftspeople, including pipefitters, ironworkers, welders, and laborers, 54 millwrights performed the majority of the work. Official project dates were March 17-April 13, and SSMRC millwrights were on site from March 18 to April 15.

“Every trade provides a specific skill set on our jobsites, and each of them is just as important as the others,” Mason said. “However, the millwrights provide the skillset to disassemble, inspect, measure, and re-assemble with precision some of the most important equipment inside the power plant and, at nearly 200 tons for the generator rotor, some of the heaviest equipment as well. They perform these tasks very well and very safely.”

Challenges

Like all projects, this one had its hurdles. Staffing challenges were chief among them, Williams said. With 17 projects in the SSMRC’s jurisdiction, the spring 2023 nuclear outage season was one of the busiest in recent history. This provided opportunities to fill positions with apprentices, and TVA encouraged an apprentice percentage as high as one third. In other industries, our partners tend to ask for apprentice percentages of up to 10% or 20%, Williams said.

“For TVA to say, ‘Hey, we will allow you to go up to a third’ was good for us,” he said. “We had some apprentices who had never been in the nuclear field. They’re now in line to continue on that path of nuclear work. So it helps us tremendously for future manpower requests in the nuclear industry.”

TVA staff could foresee benefits for their organization as well. TVA President Jeff Lyash stated last year the federally owned utility corporation plans to construct more than a dozen small modular reactors in its seven-state region. TVA has a goal of operating a carbon-free grid by 2050.

“TVA realized that unless we allow apprentices into these areas, manning them could get to a critical point,” Williams said. “Twenty-six percent of the nuclear millwrights in the Southern States are over the age of 55. So there’s a lot of opportunity for apprentices to join those ranks because every year we’re going to have people retiring.”

Wolfe, a third-year apprentice with Millwright Local 1554 who had never worked at a nuclear site before, said he plans to specialize in nuclear work going forward. He’ll do other work, too, since nuclear jobs aren’t available all the time.

“I really liked how everyone worked well together and how I felt like I was part of a team,” Wolfe said. “It makes me want to follow the nuclear line.”

At the all-hands meeting before the Sequoyah outage began, Williams challenged journey-level millwrights to become mentors. “And then the challenge to the apprentices was to become a much better apprentice and to learn as much as they could from those journeymen,” Williams said.

Even though he had worked on gas and steam turbines, Wolfe said there was a significant amount to learn on his first nuclear job. Journey-level millwrights, craft labor superintendents, and Siemens personnel were all patient and informative, he said.

“They really made sure that you had an understanding of what you were doing,” Wolfe said. “And they didn’t make you feel stupid if you didn’t know something.”

Wolfe said he was particularly impressed with how safety-oriented the project was.

Mason said Siemens’ focus is always on safety first, especially when dealing with the challenges most nuclear-turbine projects present, from stuck coupling bolts, galled studs, and tooling issues to the rigging and lifting of major components. “The professional and highly skilled and trained UBC millwrights who work for Siemens Energy on these projects are our biggest asset to completing the work scope in a very safe, quality manner and on or ahead of schedule,” he said.

Contractor relationship

Siemens and the SSMRC have a broad, long-running relationship.

“We work hand in hand on not only nuclear-power generation, but also gas turbines, steam turbines and wind turbines,” Williams said. “They’re one of the top contractors in North America not only for the SSMRC but the UBC, so we have a very good working relationship.”

In recent years, the two organizations have worked together to improve retention and recruitment, Mason said. “We’ve seen and discussed the attrition among not only the craftspeople but our Siemens Energy personnel as well through retirements, career path changes, and the pandemic, which stopped many from traveling,” he said. “We have all made changes to attract motivated and enthusiastic personnel so that we may all continue to be the service provider of choice in the nuclear-turbine-generator service business.”

Wolfe said Siemens staff seem to genuinely care about workers and listen to what they have to say. The Sequoyah outage was Wolfe’s first experience working for Siemens, and he worked for the company again later in the spring, at the WA Parish Gas Fired Steam Turbine Power Plant in Texas.

Future outlook

Siemens Energy’s goal with the TVA nuclear plants is to modernize the turbines as much as possible in coming years so the utility can reliably and affordably generate every possible megawatt through improved design and efficiency, Mason said. “There will be no shortage of work for the skilled tradesperson, in my opinion,” he added.

See something, say something

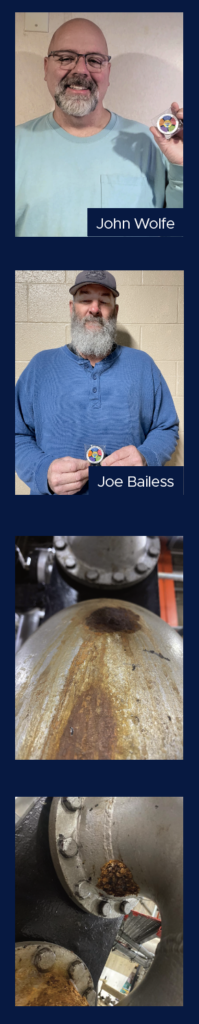

Millwrights John Wolfe of Local 1554 and Joe Bailess of Local 1607 weren’t responsible for inspecting the seal oil cooler reversing heads while they were working on a low-pressure turbine at Sequoyah Nuclear Plant’s Unit 2, but when they saw corroded and possibly leaking pipelines, they notified a supervisor.

“We dealt with the oil seal valves, which are right next to these pipelines,” Wolfe said. “The valves pump fluid into the pipelines.”

The corrosive seal oil leaking from one pipeline had dripped onto another, seriously damaging it.

“In our union training, the instructors stress the fact that if something doesn’t look right, you should call a work stoppage and notify someone,” Wolfe said. “We didn’t have to stop what we were doing, but we did notify a supervisor right away.”

TVA employees were there within 15 minutes.

“The plant investigated the issue and did indeed find that the reversing head had corroded to the point it had a through-wall leak,” said Richard Mason, Siemens Energy TVA Nuclear Alliance manager. “The fact that it was noticed early and brought to the plant’s attention allowed TVA to make the repair and start the system without delay to operations.”

If the millwrights hadn’t made this “good catch,” TVA likely would have had to rely on backup systems or divert power from another source, said Steve Williams, nuclear representative for the SSMRC. Some customers might have even lost electricity.

TVA supervisors recognized Wolfe and Bailess and presented them with challenge coins at a morning safety meeting attended by all craft personnel and Siemens staff.

“It was fantastic to be called out, especially for me, being new,” Wolfe said. “I really felt like I did something.”

This kind of recognition benefits individual millwrights, the SSMRC as a whole, and partnering contractors, Williams said. “People like to feel appreciated,” he said. “That makes them better millwrights down the road, creates better crews, and puts us in a good light to get more work because the customer realizes we possibly saved them millions.”