Calder Manley is a 33-year-old military veteran who has been a millwright and member of Local 1192 for six years. He currently works as a millwright steward at the $1.6-billion Mazda-Toyota manufacturing plant under construction in Huntsville, Alabama, where he lives.

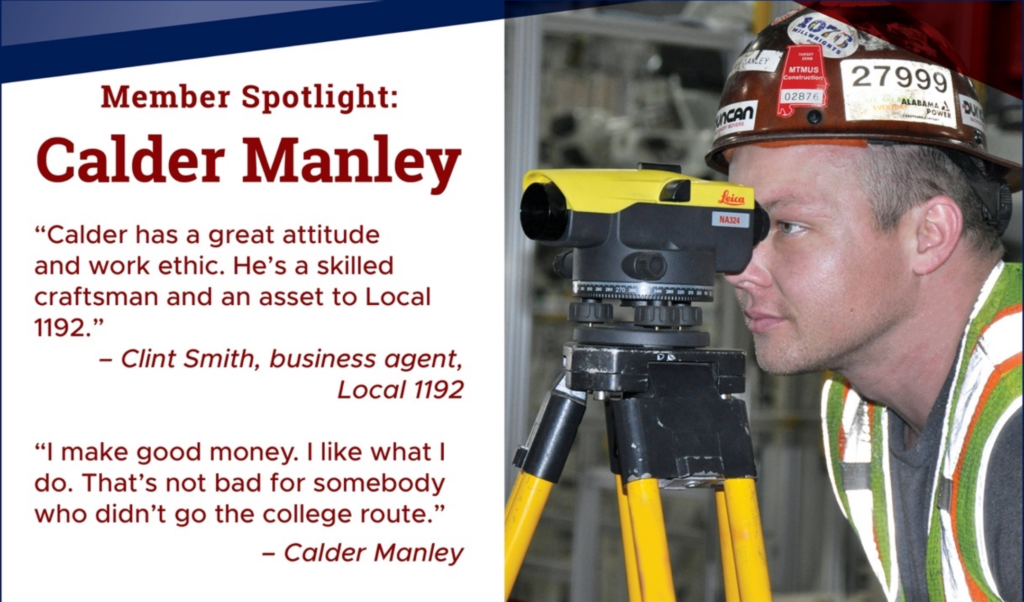

“I’m very happy with what I’m doing,” Manley says of being a millwright. “I make good money. I like what I do. That’s not bad for somebody who didn’t go the college route.”

Clint Smith, business agent for Millwright Local 1192, said Manley has a great attitude and work ethic. “He’s a skilled craftsman and an asset to Local 1192,” Smith said.

Read more about Manley in the conversation below.

Q: What got you interested in this career?

A:I had just gotten out of the Army and was looking for a job when Windale Roberts, the father of a kid I grew up with, Gabe Roberts, called and asked me if I wanted to be a millwright. I said, “What’s a millwright?” He got me started in it, and I just took to it.

Q: What do you like best about millwright work?

A:I like that you get to work with your hands, and then, when you’re done, you can step back and look at it. You can see what you’ve done, see your progress.

With my current job, I like it all. I like shooting in robots, getting them on elevation, leveling them. I like the layout. I don’t like doing the same thing for an extended period of time. If I do layout for a week, I’m ready for something different. Same thing with shooting robots. I like to change it up, be versatile. So far, this job has allowed me to do that.

Q: What kind of millwright work have you done and where?

A:Mostly what I’ve done has been conveyor work for FedEx and UPS and a lot of stuff in Toyota facilities. I’ve worked all the way from Connecticut and Pennsylvania, down to Florida, and over to Texas and Oklahoma.

With FedEx and UPS, it’s all conveyor work. Toyota has some conveyor, but there’s also a lot of robots and different machines you have to lay out and work with.

Q: How long were you in the military and what did you do?

A:I was in the Army four years, and I was a heavy machine gunner in the infantry. I carried an M240B. I deployed to Afghanistan for one year. Basically, we set up and ambushed guys trying to implant IEDs (improvised explosive devices) along the roads that we would travel on. If there was a popular spot, we would go and set up and wait for them to try to implant IEDs.

Q: Did any of your military training translate to your work as a millwright?

A:Just the discipline aspect of doing this kind of work. This work can be very frustrating at times. There are guys who get frustrated easily and they’ll stop working or quit the job sometimes. You just can’t give up like that.

Q: How do you feel about being a millwright?

A:I love it. I don’t know of anything that I would enjoy more – other than getting paid not to do anything, and life doesn’t work like that.

Q: I understand you’re a steward on your current job. How do you feel about holding leadership positions as a millwright?

A:I feel like I’ve had enough experience now to hold these positions and do well at them.

Q: What are your plans and hopes for your career going forward?

A:Well, I’m hoping that I’ll be able to be a foreman. If I get to continue to work for Trade-Mark Industrial, I’m hoping to be in the shop up here and possibly run the shop one day.

Q: Tell us about your family.

A: My wife is Karli Manley, and we’ve been married almost two years. It will be two years Aug. 18. My mom is Dana Holaday, and my stepdad is Matt Holaday. To my parents and Karli, I want to say: Thank you for having faith in me and sticking with me through the hard times.