More than $20 million is being invested in new union millwright training centers and training-center upgrades across the Southeast. These investments will address the shortage of skilled industrial construction workers affecting many areas and help contractors and facility owners staff projects with elite craftspeople who have the specialized skills needed to complete work safely, properly and in a timely manner.

New training centers, each representing an investment of more than $5 million, are being constructed in Charlotte, North Carolina, Russellville, Arkansas, and Nashville, Tennessee. Training center upgrades, which include new, state-of-the-art equipment, have been completed or are underway in Tampa, Florida, and both Houston and Arlington, Texas.

The Southern States Millwright Regional Council currently trains millwrights at 20 strategically located facilities.

“The SSMRC’s value proposition to our business partners is that we will help them meet their goals by providing the safest, most productive and professional millwrights on every project,” said Wayne Jennings, executive secretary treasurer of the Southern States Millwright Regional Council. “To do this, we need to keep pace with technology changes, and that requires continued, top-level training. That’s why our organization has invested millions in our affiliated training programs in recent years and will continue to do so.”

Up-to-date, specialized training

When planning and upgrading training facilities, the SSMRC and its training staff not only consider the technology currently in the field, but what’s on the horizon, said William Grimm, executive director of the Millwright Contractors Association. “The investment in training initiatives is demonstrating a real desire to deliver on that,” he said. “Customers are very clear that they expect millwrights to have a specific skill set and be ready to safely perform that work,” he said. “The SSMRC and its training centers provide very advanced skills and safety training with the goal of providing a millwright who shows up to the job ready to perform it safely and competently.”

The SSMRC’s training arm even offers customized training based on unique projects and jobsite needs, and the training center investments will enhance those capabilities, said Greg Williams, training director for the SSMRC’s Central Region. “We can provide a trained work force ready to tackle any job task our contractors secure at any plant or on any jobsite,” he said.

Shon Douglas, training director for SSMRC’s Eastern Region, said custom training programs are often developed to target specific and unique needs. “We can tailor any type of program just for one particular contract,” he said. “We’ve put together training for specific risks that weren’t even in the OSHA book because the hazard was brand new.”

Focus on safety

Grimm said the emphasis the SSMRC and the training program place on safety is extremely valuable to contractors and their customers. “Safety has primacy in all the curriculum, not only at training centers, but on the work sites,” he said. “If that’s not provided, that exposes the worker and co-employees to the potential of being injured or worse, and that is on the minds of everyone, including the contractors and the customers we serve.”

Another advantage of working with SSMRC millwrights is that their skills and safety training are clearly documented, Grimm said. “This documentation communicates exactly what experiences each millwright possesses, so it allows contractors to aim the correct workers at each project,” he said.

Combating the skilled-worker shortage

The skilled-industrial-construction-worker shortage in many areas means contractors can struggle to staff projects and might pay higher costs associated with bringing in workers from other parts of the country – or accept workers with training deficits, which can have negative impacts on safety, productivity, the bottom line and a company’s reputation. The expanded training capacity the new and upgraded centers provide will increase the number of highly skilled millwrights available throughout the South, said Logan Brown, Eastern Region director for the SSMRC.

“The training center investments will provide more opportunities for people to get the skills they need in the geographic areas where the work is going on,” Brown said.

Douglas said the new Charlotte facility will likely result in many people choosing an industrial-construction career when they otherwise would not have. “It’s either that or a technical college, and one of our big selling points is when you get done with your four-year apprenticeship, you don’t owe anything,” he said. “You have people who want to work and make a living while they’re going to school. And on top of that, you have benefits – insurance and pension – to go along with the apprenticeship.”

Brown said SSMRC maps reveal large concentrations of members around the organization’s existing training centers, and the expanded training opportunities the new and upgraded facilities afford should add to and increase those member-density areas.

“It’s an investment and reinvestment that shows we are listening and our values are aligned with our industry partners’ values, with safety and training being chief among them,” Brown said.

Read on to learn more details about each training-center project.

Charlotte, North Carolina

The new, $6 million training center in Charlotte, North Carolina, began offering classes in February. The training center sits on 6 acres purchased in 2018 with help from a $300,000 grant from the SSMRC. The council also donated new training equipment worth approximately $300,000. A state-of-the-art welding shop with 10 Clean Air welding booths is part of the 25,000-square-foot facility. Welding training encompasses gas metal arc welding (GMAW/MIG), gas tungsten arc welding (GTAW/TIG), and shielded metal arc welding (SMAW/stick). Two welding booths will be certified for American Welding Society tests.

The new facility is located close to interstates 77 and 85 and will provide skilled millwrights to service the region’s power plants. “There are a lot of power plants in this area, and opportunities for millwrights are out the roof,” Douglas said.

To schedule a tour of the training center, contact Shon Douglas at sdouglas@sectt.com or 706-426-8542.

Nashville, Tennessee

Ground will be broken soon on a $5 million, 25,000-square-foot training center near Nashville, Tennessee. The training center will be built on 4 acres located on Veterans Memorial Parkway, which connects to highly visible U.S. Hwy. 41 in Lavergne, Tennessee. The SSMRC provided a $300,000 grant to help purchase the property and is donating approximately $300,000 worth of training equipment.

Like many other millwright training centers in the SSMRC jurisdiction, the Nashville facility will house a computer room where instructors will conduct site-specific NANTeL training for nuclear power plants.

Russellville, Arkansas

Construction is set to begin this year on a 20,000- to 30,000-square-foot training center in Russellville, Arkansas. The additional space the new facility will provide is needed to accommodate the growing apprenticeship program. The 4-acre site for the center is in a highly visible location close to Interstate 40. The SSMRC provided a $300,000 grant to help purchase this property, is donating approximately $300,000 worth of new training equipment and is providing $3 million for construction.

Arlington, Texas

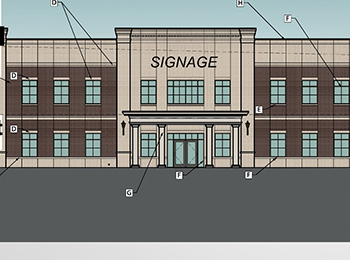

An $800,000 upgrade to the 35,000-square-foot Arlington, Texas, training center was completed early this year. The upgrade included an exterior renovation and new training equipment. The SSMRC contributed $500,000 toward the building upgrade and the new equipment.

Houston, Texas

A 2012 upgrade of the Houston training facility centered on installation of two reciprocating compressors, which SSMRC millwrights are using to train for work in the petrochemical and related energy fields. The SSMRC assisted the Houston Training Center by paying off a $1.3 million mortgage.

Tampa, Florida

A new classroom building with an auditorium is planned for the Tampa, Florida, training center. The $1.5 million to $2 million project will consist of 12,000 square feet of new classroom, auditorium and administration space. A 2,000-square-foot addition to the previously 8,000-square-foot shop facility was completed in early 2020. The expanded training space includes new welding booths. The SSMRC provided a $200,000 grant for the expansion and will provide a $300,000 grant for the new classroom/admin building.